- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

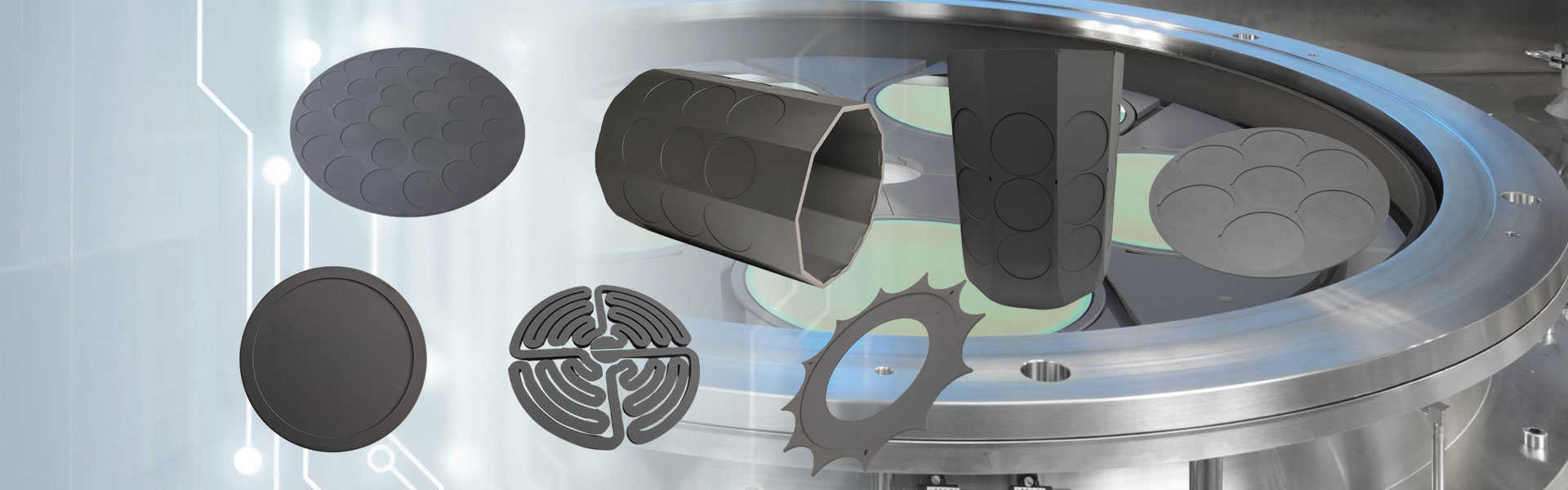

China Grafit isosatik Produsen, Pemasok, Pabrik

- View as

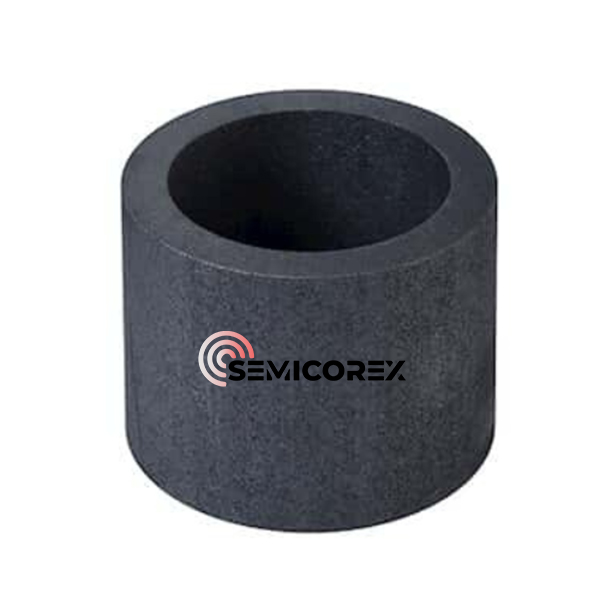

Graphite Crucible kemurnian dhuwur

Aplikasi Semicorex High-purity Graphite Crucible saka manufaktur semikonduktor nganti casting logam lan nggawe perhiasan, nggambarake fleksibilitas lan indispensability.

Waca liyaneKirim PitakonanGraphite Bipolar Plate

Semicorex Graphite Bipolar Plate minangka komponen penting ing sistem energi modern, nawakake gabungan konduktivitas listrik sing unggul, manajemen termal, lan kekuatan mekanik. Aplikasi ing sel bahan bakar PEM lan baterei aliran nyorot peran kritis ing maju teknologi energi resik.

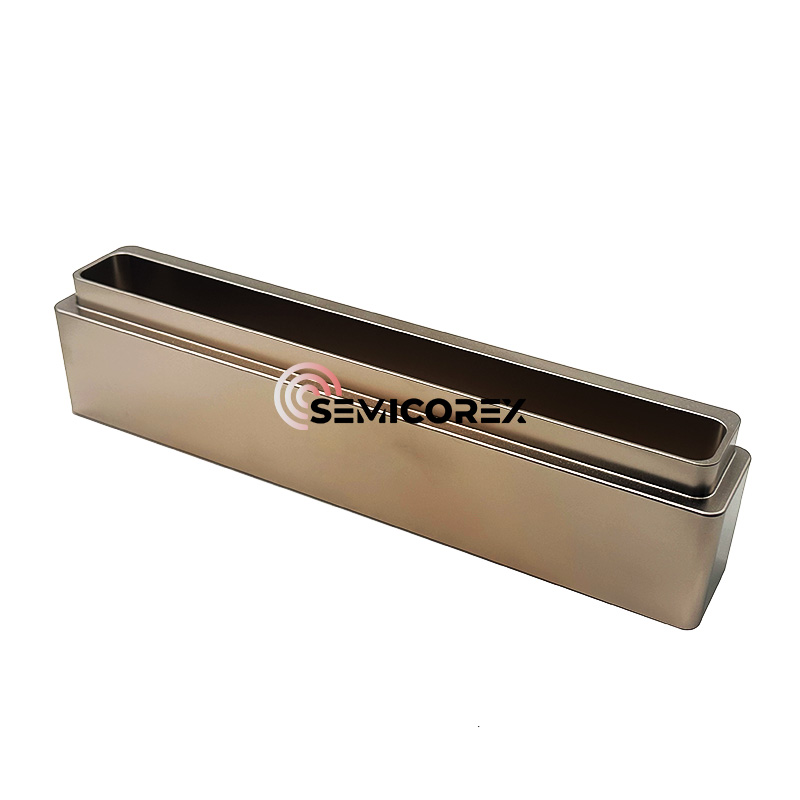

Waca liyaneKirim PitakonanCetakan Grafit Olahan

Semicorex Refined Graphite Mould minangka alat serbaguna lan efisien ing macem-macem proses casting lan cetakan industri. Kemurnian sing dhuwur, ekspansi termal sing sithik, lan permukaan sing apik banget dadi pilihan sing disenengi kanggo aplikasi sing mbutuhake presisi lan kualitas.

Waca liyaneKirim PitakonanPotongan Biji Grafit

Potongan Biji Graphite nduweni peran kritis ing produksi polysilicon kelas elektronik, utamane ing sistem pemanasan tungku kristal tunggal.

Waca liyaneKirim PitakonanImplan Ion Grafit

Semicorex Graphite Ion Implanter minangka komponen kritis ing bidang manufaktur semikonduktor, dibedakake kanthi komposisi partikel sing apik, konduktivitas sing apik, lan tahan kanggo kahanan sing ekstrem.

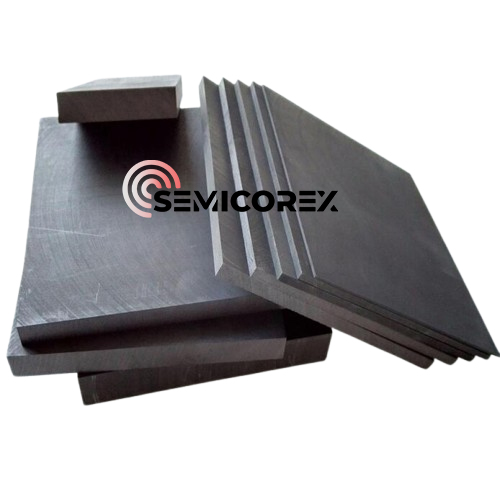

Waca liyaneKirim PitakonanPlat Isolasi Grafit

Kombinasi unik saka Semicorex Graphite Insulation Plate ndadekake bahan serbaguna lan penting ing spektrum industri sing akeh.

Waca liyaneKirim Pitakonan